Demand planning helps companies plan and manage their supply chain and sales. The goal is to reduce costs while improving service levels. The process involves three main components: sales forecasting, inventory management, and supply chain management. It can help businesses improve their planning and reduce inventory.

Demand planning is a combination sales forecasting, inventory management, and supply chain management.

Demand planning is a crucial component of supply chain management and involves the systematic study of customer demand and inventory levels. It involves evaluating a range of factors, such as seasonal shifts and economic conditions. When done correctly, demand planning helps retailers remain competitive and take advantage of sales opportunities, while minimizing waste and improving operational efficiencies. Additionally, it helps retailers allocate resources more efficiently and make adjustments in real time. To accurately forecast demand, it is necessary to have a lot of data. Retailers must have the infrastructure and tools to collect and analyze this data.

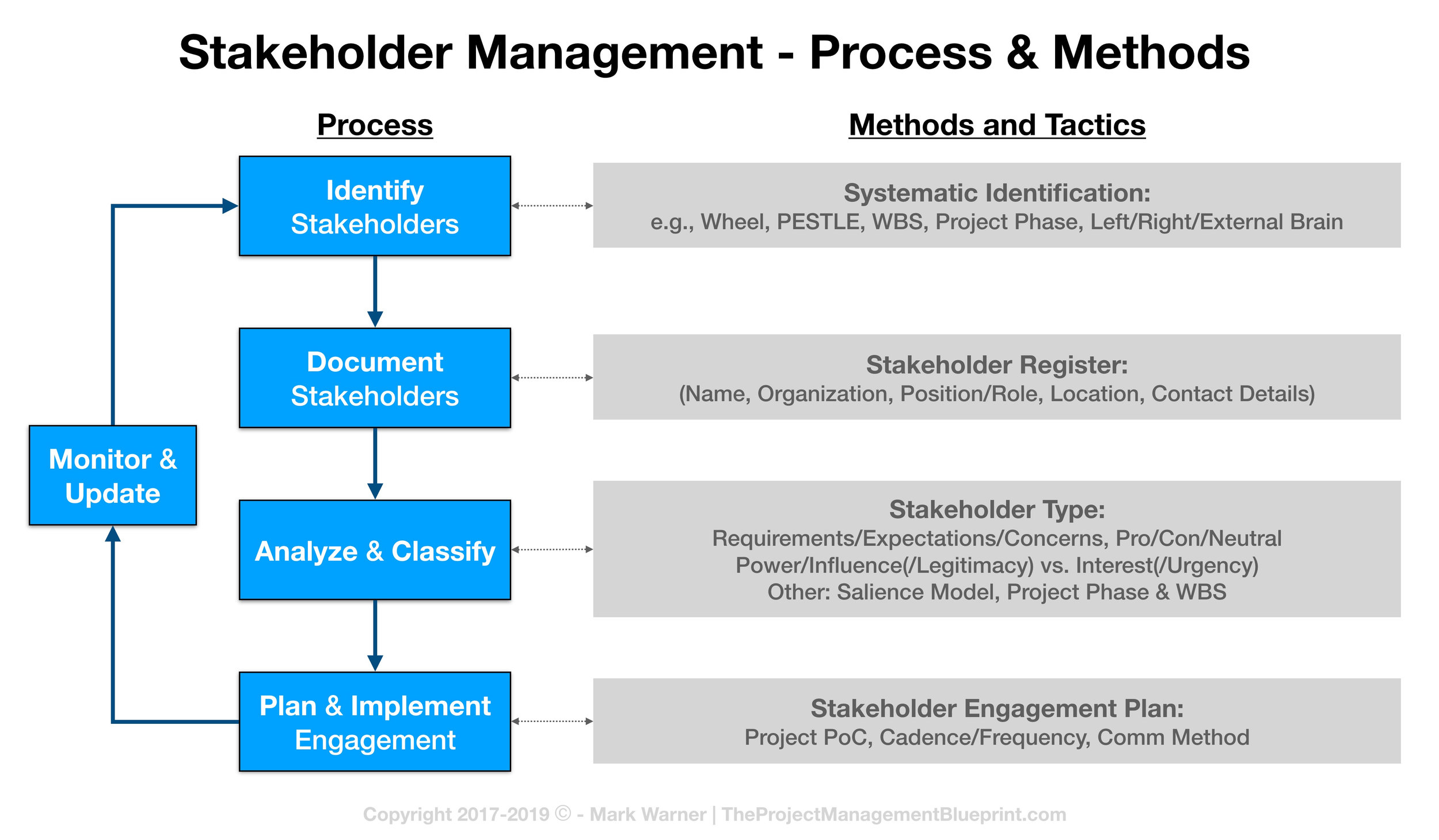

The process of developing a demand plan requires data collection from all departments. It also involves monitoring market changes and engaging the relevant stakeholders. For success, demand planning should be integrated with inventory management and supply chain management.

It helps companies plan operations better

For businesses to balance inventory and customer demand, it is crucial to have a demand planning process. It requires coordination from all departments. Unnecessary inventory can lead to lost revenue and higher inventory carrying costs. This increases the likelihood of having obsolete or low-value inventory. Poor demand planning may also cause disruptions in the supply chain, stockouts, and costly scrambles when trying to source raw material. This can ultimately result in unhappy customers.

To do demand planning correctly, companies must gather and analyze data about past sales, seasonality, and customer trends. This data can be combined with inventory control to improve forecasting and make more informed purchasing decisions.

It lowers costs

The best way to cut costs is demand planning. Not only will it reduce production costs but it also helps to save money on warehouses. It also helps companies keep their inventory levels more manageable by having fewer items on hand. This is how you can implement demand planning within your business. Remember to communicate well.

A good demand plan will allow you to balance customer demand and inventory. This requires collaboration across the entire organization. If you don't plan well, your company might end up with excessive inventory. This can lock up working capital and increase inventory carrying costs. It could also lead your company to have low-value inventory, or even obsolete products. Additionally, poor planning can lead to supply chain disruptions, stockouts, and costly scrambles to secure raw materials. Delays can cause customer dissatisfaction.

It improves service levels

It is essential that retailers plan the demand for a product in order to meet their customers' needs. Planning the demand for a product helps retailers to manage inventory, purchasing, storage, and other processes. It helps improve forecasting by indicating how much stock is necessary for a product. Once a business has established a workable demand planning process, it can easily be used to guide sales and operations planning.

FAQ

How do you effectively manage employees?

Achieving employee happiness and productivity is key to managing them effectively.

This also involves setting clear expectations and monitoring their performance.

Managers must set clear goals for their employees and themselves to achieve this goal.

They need to communicate clearly and openly with staff members. They need to communicate clearly with their staff.

They must also keep track of the activities of their team. These include:

-

What did we accomplish?

-

How much work were you able to accomplish?

-

Who did it, anyway?

-

How did it get done?

-

Why was it done?

This information can be used for monitoring performance and evaluating results.

What is a management tool to help with decision-making?

A decision matrix is an easy but powerful tool to aid managers in making informed decisions. They can think about all options and make informed decisions.

A decision matrix allows you to represent alternatives as columns and rows. It is easy to see how each option affects the other options.

In this example, there are four possible options represented by boxes on the left-hand side of the matrix. Each box represents an option. The top row represents the current state of affairs, and the bottom row is indicative of what would happen in the event that nothing were done.

The effect of choosing Option 1 can be seen in column middle. In this case, it would mean increasing sales from $2 million to $3 million.

The results of choosing Option 2 and 3 can be seen in the columns below. These are both positive changes that increase sales by $1million and $500,000. They also have negative consequences. Option 2, for example, increases the cost by $100 000 while Option 3 decreases profits by $200 000.

The final column shows the results for Option 4. This will result in sales falling by $1,000,000

A decision matrix has the advantage that you don’t have to remember where numbers belong. You just look at the cells and know immediately whether any given a choice is better than another.

This is because the matrix has already taken care of the hard work for you. It's simply a matter of comparing the numbers in the relevant cells.

Here's a sample of how you might use decision matrixes in your business.

You want to decide whether or not to invest more money into advertising. If you do this, you will be able to increase revenue by $5000 per month. However, this will mean that you'll have additional expenses of $10,000.

You can calculate the net result of investing in advertising by looking at the cell directly below the one that says "Advertising." That number is $15 thousand. Advertising is a worthwhile investment because it has a higher return than the costs.

Why is it so hard to make smart business decisions?

Complex systems and many moving parts make up businesses. They require people to manage multiple priorities and deal with uncertainty and complexity.

The key to making good decisions is to understand how these factors affect the system as a whole.

To do this, you must think carefully about what each part of the system does and why. It is important to then consider how the individual pieces relate to each other.

Ask yourself if there are hidden assumptions that have influenced your behavior. If they don't, you may want to reconsider them.

You can always ask someone for help if you still have questions after all of this. They might see things differently than you and may have some insights that could help find a solution.

Statistics

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

External Links

How To

How does Lean Manufacturing work?

Lean Manufacturing uses structured methods to reduce waste, increase efficiency and reduce waste. These processes were created by Toyota Motor Corporation, Japan in the 1980s. The primary goal was to make products with lower costs and maintain high quality. Lean manufacturing focuses on eliminating unnecessary steps and activities from the production process. It includes five main elements: pull systems (continuous improvement), continuous improvement (just-in-time), kaizen (5S), and continuous change (continuous changes). Pull systems allow customers to get exactly what they want without having to do extra work. Continuous improvement is the continuous improvement of existing processes. Just-intime refers the time components and materials arrive at the exact place where they are needed. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. The 5S acronym stands for sort in order, shine standardize and maintain. These five elements can be combined to achieve the best possible results.

Lean Production System

The lean production system is based on six key concepts:

-

Flow is about moving material and information as near as customers can.

-

Value stream mapping - Break down each stage in a process into distinct tasks and create an overview of the whole process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban - use visual signals such as colored tape, stickers, or other visual cues to keep track of inventory;

-

Theory of constraints: Identify bottlenecks and use lean tools such as kanban boards to eliminate them.

-

Just-in-time delivery - Deliver components and materials right to your point of use.

-

Continuous improvement - incremental improvements are made to the process, not a complete overhaul.