Supply Chain Management Review is an American business magazine that covers supply-chain trends. It provides a broad overview of the supply chain and the role played by suppliers and manufacturers. This magazine also provides an in-depth view of current trends and technologies. SCMR's website has more information. You can download the most recent edition. If you're looking for industry insight, subscribe to the magazine today.

Autonomous mobile robots

AMRs are a rising trend in warehouse automation. They will likely have a major impact on many aspects. These robots can work in dynamic environments and design their own routes, which frees up labor for more valuable tasks. They can also be used to reduce manual picking and increase productivity. AMRs can reduce labor costs by eliminating the need to manually walk, which can lead to a significant increase in productivity.

Blockchain

Supply chain management is an integral part of any company's success, especially in an age of global competition. Companies must be agile, flexible, responsive and adaptable to remain competitive. Continuous innovation is a way for companies to differentiate themselves. These goals can be achieved by improving the efficiency of the entire supply-chain. Blockchain technology is one method to accomplish this. Blockchain can be shared with many people, much like a Google document. This allows users to make changes at any time.

Real-time data

Supply chain management has changed rapidly. Real-time data is a great tool to assist supply chain managers in managing their businesses better. Companies can track and control inventory levels to prevent overages. Additionally, retailers can use real-time data to predict and respond in time to shipping delays. This improves customer satisfaction. Using real-time data to manage inventory and make decisions about future operations is a great way to increase business productivity.

S&OP

Supply Chain Management Review has the latest news on supply chain management. This U.S.-based business magazine covers a variety topics, including global trends. It also provides information on supply chain management techniques and tools. It is crucial to keep up with the latest trends in supply chain management for a company's success. The magazine covers the latest supply chain management trends and provides business advice.

Adapting and adapting to change

Adapting to change in supply chain management is increasingly important for business owners. The recent pandemic caused severe disruption to supply chains all over the world. There were long shut downs as a result of efforts to contain it. Supply chains have become more vulnerable to sudden shocks, such as the 9/11 terrorist attacks, dockworkers' strikes, and the SARS outbreak. Despite the complexity and importance of supply chains, many companies are not equipped for dealing with emergency situations. Many companies forget about contingency plan, which can lead to disruptions in their supply chain.

Supply Chain Management Goals

A supply chain management review can help organizations improve their ability to respond to change. Supply chains are cross-functional processes that move raw materials into and out of a business. These processes cover inventory management, transportation and returns. The ultimate goal of these processes is to minimize disruption and increase flexibility. It is also important to understand the effects of these changes on a company's profits. Continue reading to find out how supply chain management reviews can benefit your company.

FAQ

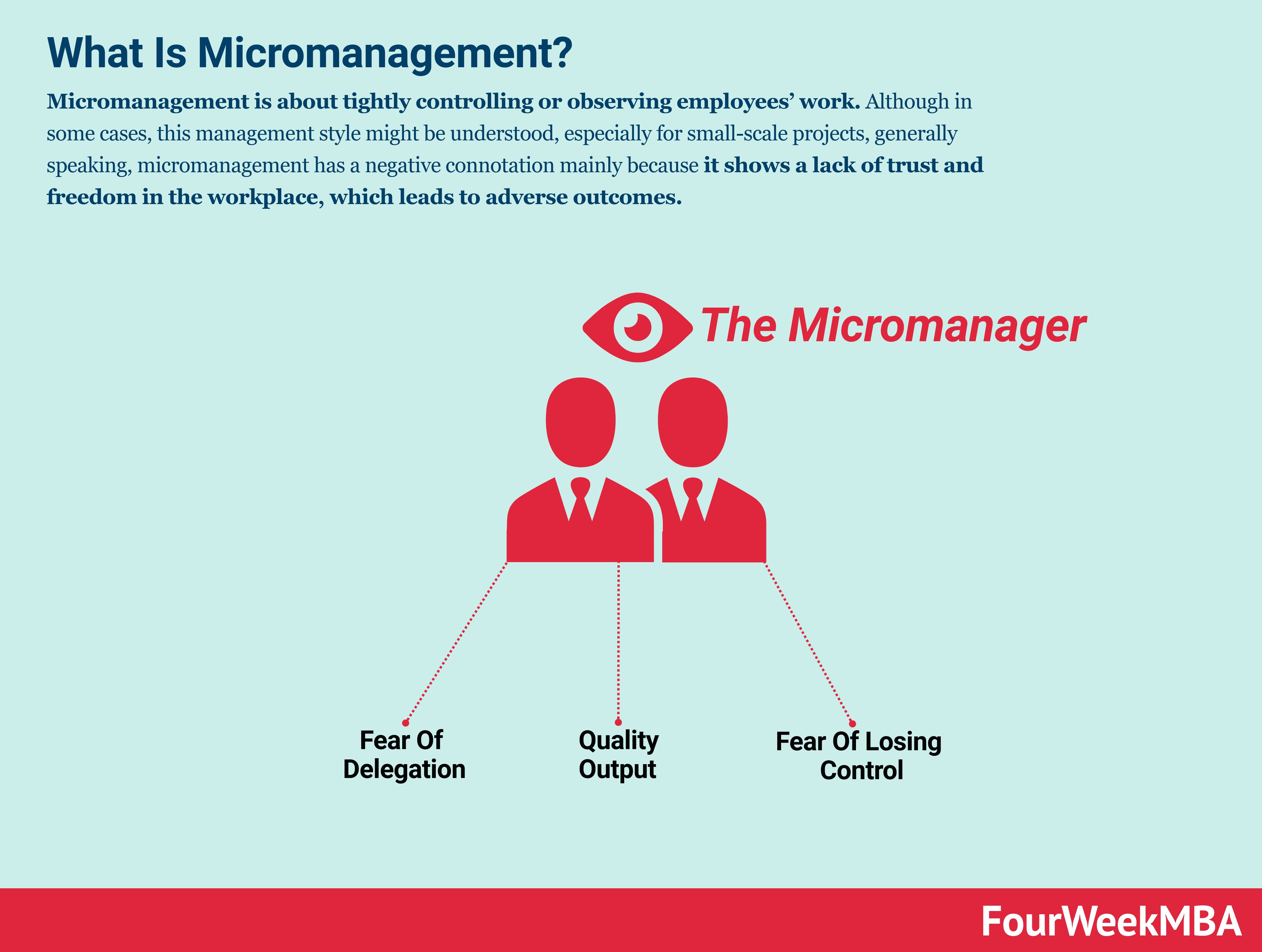

How to effectively manage employees

Effectively managing employees means making sure they are productive and happy.

This includes setting clear expectations for their behavior and tracking their performance.

Managers must be clear about their goals and those of their teams in order to succeed.

They need to communicate clearly with staff members. They should also ensure that they both reward high performers and discipline those who are not performing to their standards.

They will also need to keep records about their team's activities. These include:

-

What was achieved?

-

How much work was put in?

-

Who did it, anyway?

-

It was done!

-

Why it was done?

This information can help you monitor your performance and to evaluate your results.

What are the three main management styles you can use?

The three basic management styles are: authoritarian, laissez-faire, and participative. Each style is unique and has its strengths as well as weaknesses. What style do you prefer? Why?

Autoritarian – The leader sets the direction for everyone and expects them to follow. This style is best when the organization has a large and stable workforce.

Laissez-faire: The leader lets each person decide for themselves. This style works best when the organization is small and dynamic.

Participative – The leader listens and takes in ideas from all. This approach works best in small organizations where everyone feels valued.

What are management principles?

Management concepts are the practices and principles managers use to manage people or resources. These topics include job descriptions, performance evaluations and training programs. They also cover human resource policies, job description, job descriptions, job descriptions, employee motivation, compensation systems, organizational structures, and many other topics.

What is the difference between TQM and Six Sigma?

The main difference between these two quality-management tools is that six-sigma concentrates on eliminating defects while total QM (TQM), focuses upon improving processes and reducing expenses.

Six Sigma can be described as a strategy for continuous improvement. It emphasizes the elimination of defects by using statistical methods such as control charts, p-charts, and Pareto analysis.

The goal of this method is to reduce variation in product output. This is accomplished through identifying and correcting root causes.

Total quality management refers to the monitoring and measurement of all aspects in an organization. This includes training employees to improve their performance.

It is often used to increase productivity.

What are the five management methods?

These five stages are: planning, execution monitoring, review and evaluation.

Planning is about setting goals for your future. It involves setting goals and making plans.

Execution takes place when you actually implement the plans. These plans must be adhered to by everyone.

Monitoring is the act of monitoring your progress towards achieving your targets. This should involve regular reviews of performance against targets and budgets.

Each year, reviews are held at the end. They provide an opportunity to assess whether everything went well during the year. If not, then it may be possible to make adjustments in order to improve performance next time.

After the annual review is complete, evaluations are conducted. It helps to determine what worked and what didn’t. It also gives feedback on how well people did.

Statistics

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing techniques are used to reduce waste while increasing efficiency by using structured methods. These processes were created by Toyota Motor Corporation, Japan in the 1980s. The primary goal was to make products with lower costs and maintain high quality. Lean manufacturing focuses on eliminating unnecessary steps and activities from the production process. It includes five main elements: pull systems (continuous improvement), continuous improvement (just-in-time), kaizen (5S), and continuous change (continuous changes). Pull systems are able to produce exactly what the customer requires without extra work. Continuous improvement refers to continuously improving existing processes. Just-in time refers to components and materials being delivered right at the place they are needed. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. Five-S stands for sort. It is also the acronym for shine, standardize (standardize), and sustain. These five elements can be combined to achieve the best possible results.

Lean Production System

Six key concepts make up the lean manufacturing system.

-

Flow - focuses on moving information and materials as close to customers as possible.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S's - Sort, Set In Order, Shine, Standardize, and Sustain;

-

Kanban: Use visual signals such stickers, colored tape, or any other visual cues, to keep track your inventory.

-

Theory of constraints - identify bottlenecks during the process and eliminate them with lean tools like Kanban boards.

-

Just-in time - Get components and materials delivered right at the point of usage;

-

Continuous improvement - make incremental improvements to the process rather than overhauling it all at once.